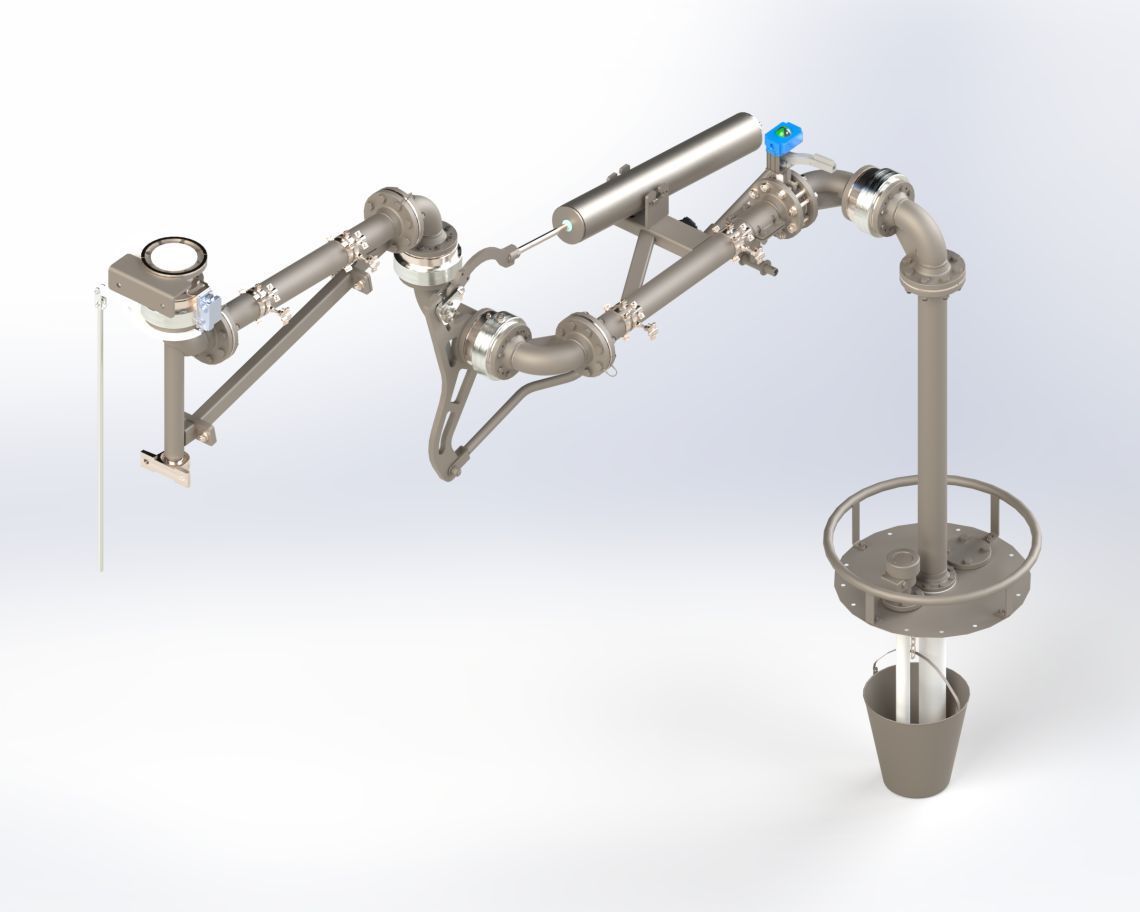

1201T Series

LOADING ARM LINED WITH TEFLON™ (PTFE)

The top loading arms series 1201T are designed to fill the tankers from above where it is necessary to have a wide range of action available. This allows maximum covering of the loading points. This type of arms, in particular, are designed for the transfer of highly corrosive chemical products and food liquids subject to strict hygiene rules. It can be made of carbon steel or Aisi 316, and, in both cases, it is internally lined in PTFE. The swivels, provided with an only one ball-bearing race, are also lined internally in PTFE with a double PTFE seal.Request the data sheet

Get the data sheet with all the product features. Fill out the form to receive the PDF.

Field of application

Designed for the transfer of highly corrosive chemical liquids.

Features

Standard configuration

- Right-hand layout, bottom inlet, ANSI 150 connecting flange.

- Base swivel T-20 style: It is used for horizontal handling It is provided with a ball-bearing race and is internally lined with PTFE with PTFE seals.

- Swivel Section: It is used to extend the range of action of the loading arm and is internally coated in PTFE.

- Double base swivel T-50 style: It is used for horizontal and vertical handling. It is made with two swivels, provided with a ball-bearing race, and is internally lined with PTFE with PTFE seals.

- Spring piston: It is used to balance the weight of the cantilever part of the loading arm

- Support tube: made of carbon steel or Aisi316, lined in PTFE.

- Safety butterfly valve: It is used to stop loading in the event of a malfunction during the supply. Body and plate are made of stainless steel coated in PTFE.

- Terminal swivel T-40 style: It is used to hold the drop pipe upright; it can be equipped with a handle to make the movement of the arm easier.

- Drop pipe: it consists of a section made of steel or Aisi316, internally lined in PTFE, and a section in PTFE only which is put into the manhole it can be equipped with a splash guard disc or a cone made of Aisi316 or PTFE.

- Drip pan

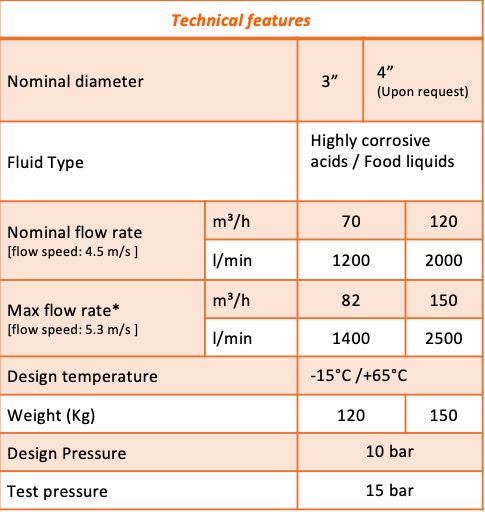

Technical features

Standards and Regulations

- Conformity Declaration of current Directive ATEX (for equipment used in Potentially explosive atmospheres)

- Conformity Declaration of current Directive PED (for pressure equipment)

- Customs Declaration of certification for Russia, Kazakhstan, Belarus, EAC certification

- Standard API-ASTM-ANSI-TTMA

Options upon request

- Arm material options: carbon steel, steel for low temperatures, stainless steel AISI 304 or AISI 316

- Upward inlet flange

- Base swivel inlet flange PN16

- Loading ball valve: made of AISI 316 lined internally in PTFE

- Special configurations for extreme temperatures (-40/+200 °C)

Accessories

- Micro switch for indication of the position of loading valve

- Microswitch to indicate vertical position

- Microswitch to indicate rest position

- Mechanical lock “Hold Down” in working position

- Mechanical Park lock in rest position

- Overfill sensor with handle

- Up/Down pneumatic actuation

- Pneumatic Valve Actuation

- Pump start/stop buttons

- Stand-post