Differential Pressure

Liquid Controls

MASTERLOAD.iQ™ Electronic Register

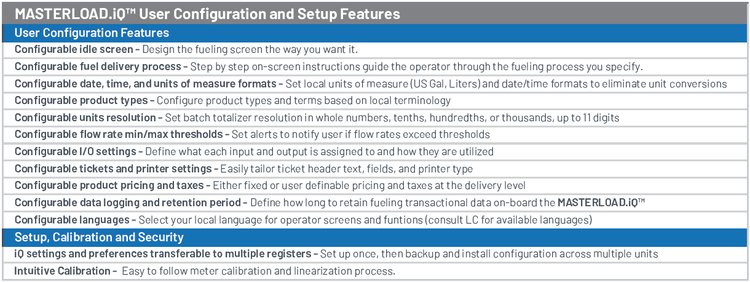

After two years of close collaboration with industry leaders, customers, and end users to develop what is now considered the new benchmark in electronic meter registration, the result is the CENTRILOGiQ® platform and the MASTERLOAD.iQ™: the most powerful and scale-able electronic register platform ever produced.

Designed with the future in mind, the ATEX Zone 2 approved MASTERLOAD.iQ™ and Zone 1 MASTERLOADx.iQ™ introduce new capabilities for OEMs and end users to fully customize the fueling experience with configurable screens and tickets, adaptable software, real-time on-screen diagnostics, and remote data access with controls, opening the door to near-infinite platform expand-ability.

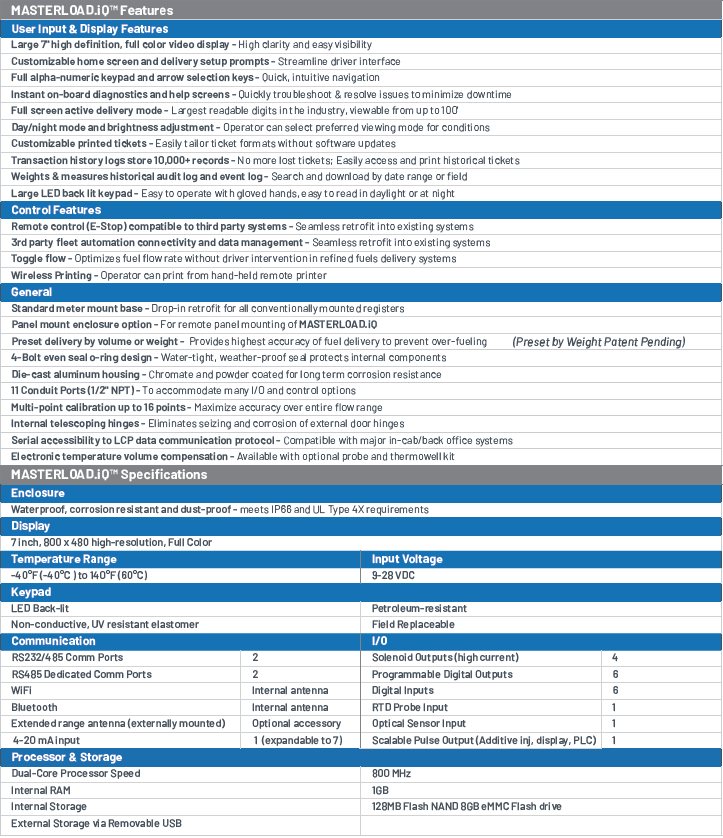

MASTERLOAD.iQ™ Features:

- ATEX Zone 1 & 2 hazardous environment options (MASTERLOADx.iQ - Zone 1)

- High visibility, large digit display in active mode

- User-configurable guided fueling processes

- Real-time on-screen diagnostics for immediate system reporting and increased up-time

- Extreme durability in harsh conditions

- Expanded digital and analog I/O for full adaptive sensing and sensor data reporting

- Wireless control and data communication via embedded Bluetooth and WiFi

IT’S JUST THAT SIMPLE.

Liquid Controls engineers took an aggressive approach by first designing the MASTERLOAD.iQ™ from the operator's perspective. The result is a user-guided, configurable interface that steps the operator through the fueling operation, maximizing efficiency and minimizing risk of error.

COMMON FUELING PROCESSES COMPLETED IN 3 STEPS OR LESS

User-configurable fueling processes control the number of steps required for the operator to complete his or her delivery. Pump and print operations are complete in two steps, using one smart-key!

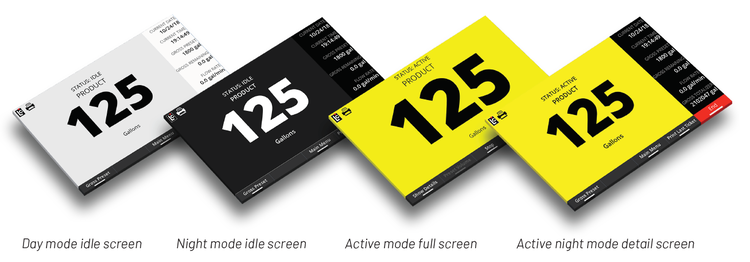

OPERATOR FRIENDLY SCREENS WITH DAY / NIGHT MODES AND BRIGHTNESS CONTROL

MASTERLOAD.iQ™ screens adapt to the operator. Idle screen shows the last delivery data, changing to full screen, active fueling mode with yellow background when "Start" is pressed. Operators have the option to see fueling details during active fueling and can easily toggle between day or night modes for reduced eye strain.

CONFIGURABILITY.

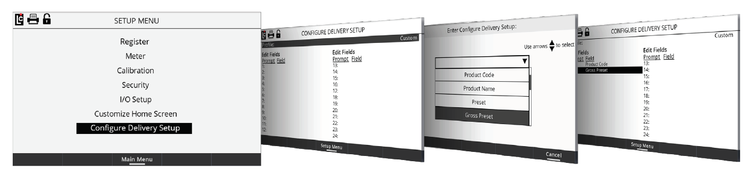

CONFIGURABLE DELIVERY SETUP

Guide the operator through the fueling process of your choosing. From basic pump and print, to preset by volume or product weight, you can also adjust price per gallon, percent tax, or select multiple deliveries on a single ticket.

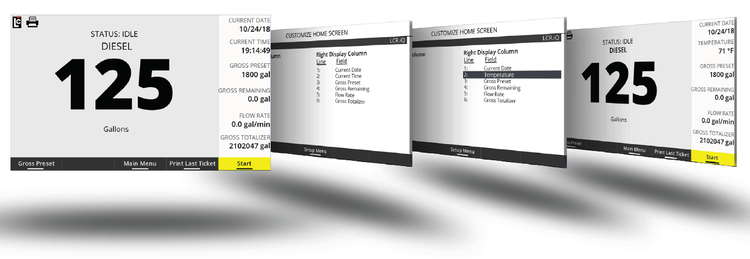

CONFIGURABLE IDLE SCREEN

Easily configure the idle screen fields the operator sees before, during, and after fueling. All units of measure including date and time formats are also configurable to comply with local standards.

ADAPTIVE SENSING TECHNOLOGY.

MASTERLOAD.iQ™ ties together essential sensing devices in aviation fueling systems that reduce complexity, improve efficiency, and monitor mission-critical safety related controls and data.

LC's electronic differential pressure (dP) transducer provides configurable control and reporting of dP across the fuel filtration system.

Electronic Differential Pressure US Patent: #7765978

Water detection, reporting, and controls per EI 1598 provides monitoring, reporting, and safeguarding from potential impact of the presence of free-water in fuel.

Shown - AFGUARD® by FAUDI Aviation

LC's Slipstream® Densitometer provides automatic fuel density and preset by weight* (or mass) fuel deliveries and reporting.

*Patent Pending

LC’s FUELiQ™ mobile app provides end-users and 3rd party data providers wireless accessibility to preset and retrieve fuelling data from a CENTRILOGiQ® register.

TECHNICAL FEATURES & BENEFITS

EU Declaration of Conformity:

MASTERLOAD.iQ is designed, manufactured, and bears CE mark in compliance with the following Directives:

ATEX Directive 2014/34/EU by application of the following standards: EN 60079-0: 2018 and EN 60079-7: 2015 As the following equipment: II 3 G Ex ec IIB T4 Gc -40°C ≤ Tamb ≤ +60°C IP66

EMC Directive 2014/30/EU and Radio Equipment Directive 2014/53/EU by application of the following standards: EN 50498:2010, EN 61326-1, EN 301 489-1 V2.2.0 (2017-03),EN 301 489-17 V3.2.0 (2017-03)

Request the data sheet

Get the data sheet with all the product features. Fill out the form to receive the PDF.