23/02/2024

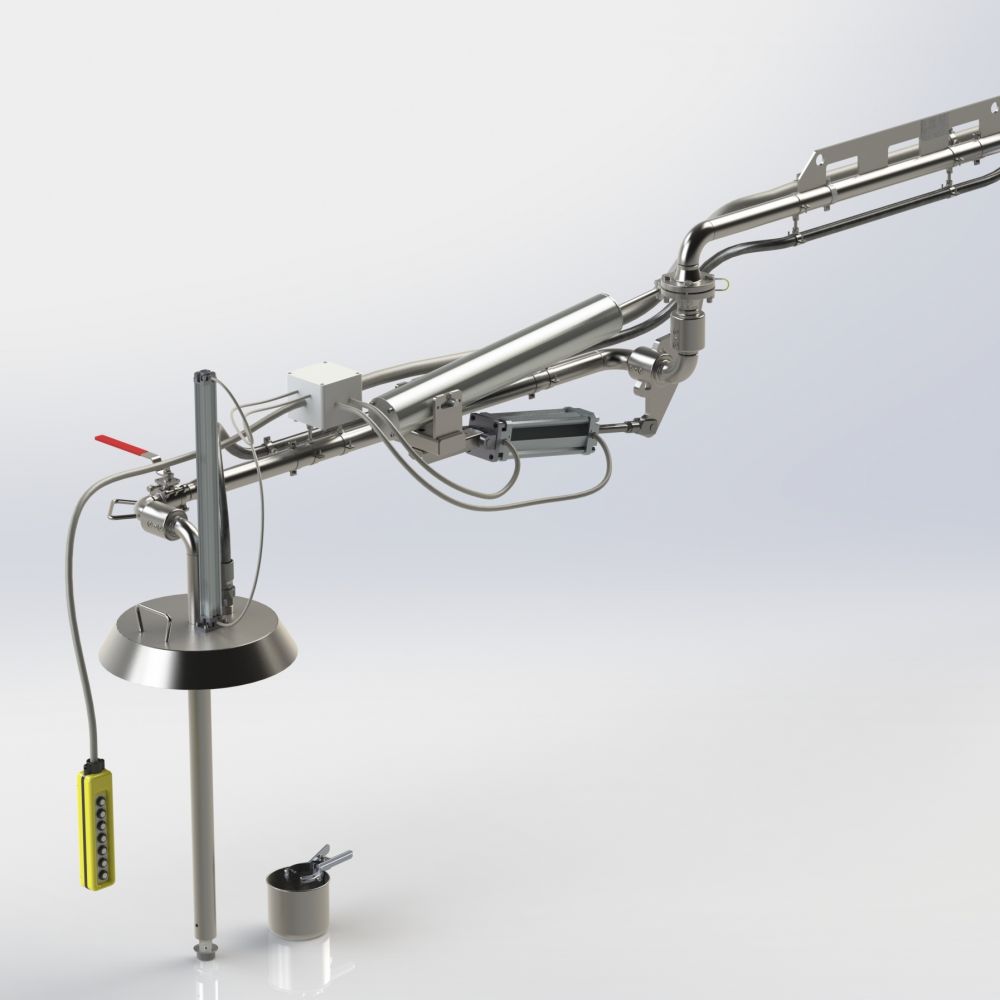

LOADING ARM FOR IBC CONTAINERS

THE CLIENT

A renowned company from Northern Europe - specializing in the industrial equipment sale, installation, and maintenance - with whom we have a history of over two decades of collaboration. As distributor, they have deep knowledge of our standard and customized products.

THEIR NEED

In this case, they requested an efficient and reliable solution for filling the IBC containers with AdBlue, an essential liquid for reducing vehicle emissions. The priority was to ensure a quick and accurate filling process.

OUR SOLUTION

To meet the client's needs, we applied our experience gained in other similar cases. We selected the loading arm from the 1201 series, the most versatile to cover a wide loading area, made of stainless steel for maximum compatibility with AdBlue. The arm was designed to optimize filling efficiency with a reduced diameter of just 2 inches, making it easily inserted into the drum to be filled and a loading capacity of 300 liters per minute.

PROJECT IMPLEMENTATION

After a detailed and collaborative design phase with the client, we initiated the production of the customized loading arm. Using high-quality materials and adhering to rigorous production standards, we ensured the product's compliance with the client's specific requirements.

THE RESULT

Although the loading arm has only recently been shipped, the distributor has expressed great satisfaction with the support provided by Silea Liquid Transfer throughout the process. The careful collaboration and adaptability to the most particular needs have further strengthened the relationship of trust and partnership between our companies.